LEAN Consulting

For many companies, the term LEAN represents nothing more than an outdated management tool from the 2000s. For most, however, lean factory concepts are now the foundation of their operational success – and we share this view. Even in the age of digitalization and artificial intelligence. With over 30 years of experience in LEAN consulting, we support hands-on companies on their path to world-class performance in production (Lean Manufacturing) or in indirect areas (LEAN Office).

Interested in LEAN? In industry and implementation examples? Simply contact me, I'm happy to help by phone or email.

Walter Meitz

+43 664 654 06 79

This email address is protected from spambots. You need JavaScript enabled to view it.

Implementation-oriented LEAN consulting

Implementation-oriented consulting represents an essential approach to supporting companies and organizations in the successful implementation of changes, projects, and strategic goals. This form of consulting focuses not only on theoretical concepts but also on the practical realization of projects. Implementation-oriented consulting is characterized by going beyond the mere development of ideas and strategies. Its main objective is to guide the practical implementation of changes and ensure that the planned measures are successfully put into practice. This approach requires close collaboration between consultants and employees at all levels of an organization.

Advantages of implementation orientation

- Practical solutions: Instead of abstract theories, concrete solutions are developed that meet the specific needs and challenges of a company.

- Faster results: Focusing on implementation leads to faster results and ensures that changes are carried out more efficiently.

- Employee engagement: Involving employees in the implementation process leads to greater engagement and stronger identification with the changes.

- Measurable success: Implementation-oriented consulting emphasizes measurable results and success monitoring, which enables continuous improvement.

- Sustainability: The solutions developed are often more sustainable because they are actively shaped and adopted by the employees.

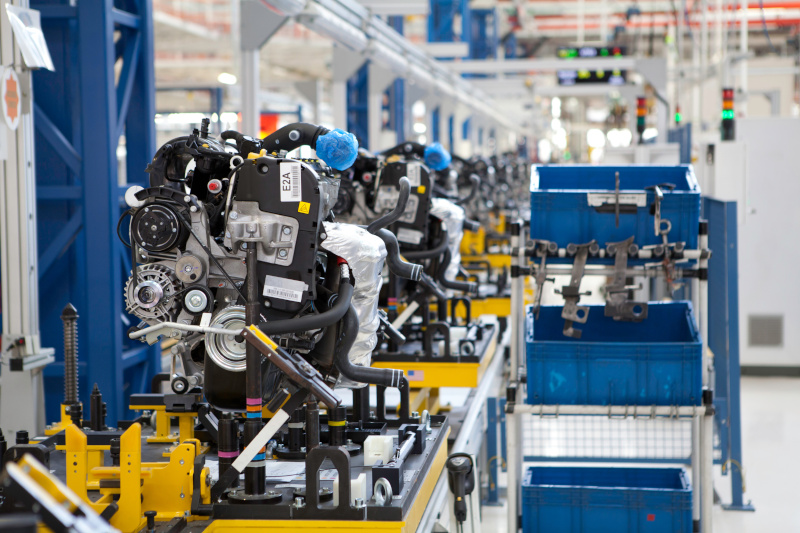

LEAN PRODUCTION

In today's business world, where efficiency and competitiveness are of central importance, the consistent implementation of the LEAN Production philosophy has established itself as an indispensable approach for companies operating at a world-class level.

Lean production is a powerful approach that helps companies optimize their production processes, reduce waste, and achieve sustainable efficiency gains. By applying lean principles, companies can not only lower costs but also strengthen their competitiveness and ensure higher product quality. In a constantly changing business world, lean production is a proven way to operate with a future-oriented and successful approach.

Lean Production consulting and training from a single source

In an increasingly competitive economy, optimizing production processes is essential. Our consulting services in the area of Lean Production help companies reduce waste, streamline processes, and create more value sustainably. But we go a step further: In addition to strategic consulting, we offer comprehensive training programs that empower your employees to effectively implement the principles of Lean Production.

Consulting: Tailor-made lean strategies for your company

Our approach begins with a precise analysis of your existing processes. Together, we identify optimization potential and develop a customized roadmap tailored to the specific requirements of your company. Whether it's introducing Kanban, just-in-time principles, or implementing 5S – we support you from conception to implementation.

Training: Lean competence at all levels

Sustainable success arises when all employees internalize the Lean philosophy. Therefore, we offer practical training courses for different target groups – from shop floor employees to management. Our training courses include:

- Fundamentals of Lean Production: Introduction to the principles and tools

- Kaizen workshops: Making continuous improvement tangible

- Value Stream Mapping: Optimizing the Value Chain

- Leadership training: Lean leadership for sustainable cultural change

Your added value

By combining consulting and training, you not only receive optimized processes, but also a team that continuously improves them. Our expertise is based on more than 200 successfully implemented projects – from medium-sized companies to global corporations.

Focus on efficiency and expertise. Contact us today to launch your Lean Production strategy together.

LEAN principles

Value orientation is the foundation of Lean Production and places the customer at the center of all business activities. The concept begins with the fundamental question: What exactly does the customer value about the product or service? In this context, "value" is understood as something the customer is willing to pay for because it fulfills their needs or solves their problems. Companies must delve deeply into the customer perspective to accurately understand these needs and define which aspects of the product or service actually create added value.

A company that takes value creation seriously ensures that every step in the production process is directly aimed at creating that value. This includes minimizing or completely eliminating non-value-adding activities that offer no direct benefit to the customer. These activities are often considered waste and can be categorized as overproduction, waiting times, unnecessary transportation, excess inventory, over-processing, unnecessary movement, and errors. By focusing strictly on value creation, companies can use their resources more effectively, increase customer satisfaction, and ultimately enhance their competitiveness.

Value stream mapping is a strategic tool in lean production that helps companies examine the entire production process and understand how value flows – from raw material intake to delivery of the finished product to the customer. The goal of this analysis is to map and evaluate each individual step in the process in order to reveal the actual value streams and any inefficiencies that arise.

This process typically begins with the creation of a value stream map, which depicts all activities in the production flow, both value-adding and non-value-adding. By visually representing the value stream, companies can easily identify bottlenecks, unnecessary waiting times, redundant work steps, and other forms of waste. Based on this, they can then take targeted measures to increase efficiency, reduce lead times, and improve the flow of production. Value stream mapping is not only a tool for problem identification but also an essential step in planning and implementing strategic improvements and optimizations throughout the entire production process.

The flow principle is a central pillar of lean production and aims to design the production process in such a way that materials and information flow continuously and without interruption through the value chain. This principle is based on the understanding that interruptions in the production flow – whether due to bottlenecks, waiting times, or inefficient workflows – lead to significant waste and can reduce the overall efficiency of production.

An optimized flow means that each production step transitions seamlessly into the next, without the need for intermediate material storage or idle resources. This requires careful planning and synchronization of production processes to ensure that all resources—machines, materials, and labor—are always available and utilized optimally. A continuous flow reduces production time and minimizes costs, as fewer resources are needed to manage intermediate inventory and waiting times. Furthermore, a smooth production process helps increase the company's flexibility, enabling it to respond more quickly to changes in demand.

The pull principle is another key concept in lean production, aiming to align production and inventory strictly with actual demand. Instead of producing large quantities of products on spec and based on forecasts (as is the case with the push principle), the pull principle only manufactures products when there is concrete demand. This ensures that only what the customer actually needs is produced, thus preventing overproduction and the associated high storage costs.

The pull principle requires close coordination and communication throughout the entire supply chain to ensure that the necessary materials and components are available precisely when needed. This not only reduces inventory requirements but also the risk of being stuck with unsold products that may become obsolete or no longer meet current customer needs. Furthermore, the pull principle enables greater flexibility and responsiveness, as companies can quickly adapt their production to changes in demand without risking high upfront costs. It promotes more efficient resource utilization and supports just-in-time production, where materials and parts are provided at exactly the right moment to support the production process.

Continuous improvement, known as Kaizen, is at the heart of Lean Production and embodies a philosophy based on constant, incremental improvement. Kaizen is more than just a process; it's an attitude and a corporate culture that aims to optimize every aspect of production and business operations. This approach emphasizes that it's not necessarily the large, radical changes that make the biggest difference, but rather the sum of many small improvements implemented continuously and consistently over time.

Kaizen encourages every employee in the company, regardless of their position, to actively seek opportunities to improve workflows, processes, quality, and efficiency. By involving all employees in the improvement process, not only is productivity increased, but also the motivation and engagement of the workforce is fostered. This collective effort leads to a dynamic, learning organization that can respond flexibly to change and grow continuously. Kaizen also promotes an open communication culture in which suggestions and ideas from all levels of the company are welcome and actively encouraged. Ultimately, this philosophy leads to the continuous development of the company, enabling it to remain competitive in the long term and to respond proactively to market changes.

Benefits of using LEAN Management

Lean principles help companies streamline their processes and eliminate waste in all its forms. By consistently focusing on value-adding activities, efficiency is significantly increased. Resources such as time, materials, and labor are used strategically and effectively. This leads not only to higher productivity but also to better utilization of existing capacities.

Focusing on continuous improvement (Kaizen) leads to the constant optimization of products and processes. Errors and defects are identified and corrected early, before they cause larger problems. Involving all employees in the improvement process fosters a strong quality culture, which is reflected in the reliability and longevity of the products.

Lean principles contribute significantly to reducing operating costs. By avoiding overproduction, minimizing inventory, and using resources efficiently, companies can substantially lower their costs. At the same time, just-in-time production enables demand-driven procurement, which generates further savings.

In a constantly changing market environment, the ability to adapt quickly is crucial. Lean methods promote flexible production, enabling companies to respond rapidly to changes in demand. Reducing lead times and optimizing processes makes it easier to bring new products to market faster and meet customer needs promptly.

Lean principles emphasize the importance of involving all employees in the improvement process. Everyone in the company, regardless of their position, is encouraged to contribute ideas for optimization. This not only fosters a sense of responsibility but also increases employee motivation and satisfaction. Such a culture of collaboration and appreciation has a positive impact on the overall work environment.

By consistently reducing waste and using resources efficiently, lean principles also contribute to environmental sustainability. Less material consumption, reduced energy costs, and optimized logistics decrease a company's ecological footprint. At the same time, continuous improvement and constant adaptability lay the foundation for long-term economic success.

Ultimately, lean production aims to put the customer at the center. By focusing on value-adding activities and improving quality, companies can offer products and services that not only meet customer expectations but often exceed them. This leads to greater customer satisfaction, which translates directly into a stronger market position and increased competitiveness.

LEAN Production Tool Box

- Value Stream Mapping

- 5S method

- Material supply

- Kaizen (continuous improvement)

- Shopfloor Management

- Assembly optimization

- SMED

Value Stream Mapping

Value stream mapping is a fundamental tool in the Lean approach. It allows you to visualize the entire production process from start to finish and identify weaknesses and non-value-adding activities. This analysis enables companies to uncover bottlenecks, shorten lead times, and reduce waste. Click here for our Value Stream Design training.

5S method

The 5S method aims to organize and standardize the workplace. It comprises the steps Sort, Set in order, Shine, Standardize, and Sustain. This method creates a clean, tidy workplace that increases productivity and safety. Click here for our 5S training.

Material supply

Kanban is a visual control system that regulates the flow of materials in production. It relies on visual signals such as cards or boards to indicate material requirements. This helps reduce overproduction and inventory while minimizing bottlenecks and disruptions.

Kaizen (continuous improvement)

Kaizen is the principle of continuous improvement. It encourages employees to constantly seek and implement opportunities for process optimization. Through small, incremental changes, companies can steadily increase their efficiency.

Shopfloor Management

Shopfloor management is a crucial approach for increasing efficiency in manufacturing. It involves the direct monitoring and control of production processes at the plant level. Through clear communication, regular meetings, and visual management methods, bottlenecks, problems, and potential improvements are identified. This enables a rapid response to optimize production processes and minimize waste. Shopfloor management also promotes employee involvement in the continuous improvement process, leading to increased motivation and effectiveness. Ultimately, this approach strengthens a company's competitiveness in a dynamic market environment.

Assembly optimization

Optimizing production processes, shortening lead times, and reducing costs. This strategy aims to make assembly processes more efficient and seamless, ultimately increasing overall production output. Assembly is a critical step in manufacturing that significantly impacts production costs, quality, and delivery times. Optimizing this process helps minimize bottlenecks, reduce production times, and increase efficiency, ultimately leading to greater customer satisfaction and competitiveness.

SMED

SMED (Single-Minute Exchange of Die) is a method for reducing setup times , aiming to lower single-digit minutes Internal and external setup processes separated to enable parallel operations. Quick-change clamping systems and optimized processes flexibility and efficiency . SMED makes production processes leaner and more economical – a benefit for every company. Click here for our SMED training/workshop.