Factory planning

The planning, optimization and realization of production and logistics sites, whether on a greenfield site or in an existing building, represents one of the most challenging tasks for companies.

Mistakes made during the planning and implementation phases are very difficult or even impossible to correct later. We support companies from site selection to the complete realization of their plants.

Walter Meitz

Your contact person for all questions, references, procedure, etc.

Walter Meitz

+43 664 654 06 79

This email address is stez protected from spambots. You need javaScript Enabled to view it.

Services offered

The term "operations footprint" refers to the entirety of a company's operational locations and activities. This encompasses not only the geographical distribution of production facilities, warehouses, and distribution centers, but also the strategic alignment of the entire value chain. An optimized operations footprint ensures that operational processes are efficient, cost-conscious, and sustainable, thereby best supporting the company's objectives.

The method for analyzing and optimizing the operations footprint begins with a comprehensive inventory. This involves a detailed recording and evaluation of all locations and their functions. The goal is to understand how each location contributes to the overall success of the company and what costs are associated with it. External factors such as market demands, supply chain risks, and geopolitical influences are also taken into account.

The next step involves a strategic assessment. The goal is to determine whether the current structure meets future requirements. To this end, various scenarios are developed that simulate different market and cost developments. These scenarios help to identify opportunities and risks and provide valuable insights into where a realignment might be necessary.

Implementing these optimization measures requires careful planning and close coordination between the departments involved. The goal is to harmonize processes, leverage synergies, and potentially reposition or even consolidate locations. Crucially, the transition must be seamless and operational continuity must be maintained.

An optimized operations footprint can not only reduce costs but also increase a company's flexibility and responsiveness. In a constantly changing global economy, this is increasingly becoming a crucial competitive advantage. Our goal is to work with you to create a future-proof structure that enables growth while meeting the demands of today and tomorrow.

**Location scouting for a new factory site** is a crucial process in a company's strategic planning. It involves the systematic search for and evaluation of potential sites that best meet the specific requirements of the planned factory. The goal is to find a location that offers the greatest possible benefit from an economic perspective as well as in terms of logistical, environmental, and social factors.

### Location Scouting Procedure

1. **Defining Location Criteria:**

The first step in location scouting is to define clear criteria that the new location must meet. These criteria can be diverse and include:

- **Cost Factors:** Land prices, taxes, subsidies, energy costs, and wage levels.

- **Logistical Aspects:** Proximity to suppliers, customers, transportation connections (roads, railways, ports, airports), and infrastructure.

- **Labor Market:** Availability of qualified personnel, training opportunities, and labor market regulations.

- **Environmental Factors:** Environmental regulations, climate conditions, energy sources, and sustainability potential.

- **Social and Cultural Factors:** Quality of life for employees, cultural compatibility, and social acceptance.

2. **Collection and Analysis of Location Data:**

Once the criteria are defined, the collection of data on potential locations begins. This includes the analysis of macro and micro factors:

- **Macro factors:** Economic stability, political framework, trade agreements, and legal aspects.

- **Micro factors:** Availability of infrastructure, specific location costs, market potential, and regional characteristics.

3. **Evaluation of Potential Locations:**

Based on the collected data, the locations are evaluated and compared. Scoring models are often used here, in which each location receives points according to defined criteria. The locations with the highest total scores are then considered for further examination.

4. **On-site visits and detailed analyses:**

The most promising locations are then visited on-site. Specific conditions are examined, such as the terrain, proximity to utility networks, and actual accessibility. Discussions are often held with local authorities and potential partners to clarify legal and organizational issues.

5. **Risk Analysis and Decision-Making:**

Before the final decision, a comprehensive risk analysis is conducted. This involves assessing potential risks such as political instability, natural disasters, supply chain risks, and social conflicts. Based on this analysis, the company then decides on the optimal location.

6. **Negotiations and Contract Conclusion:**

Following site selection, negotiations take place with landowners, local authorities, and other relevant stakeholders. The goal is to secure the best possible conditions for the company, including legal and tax frameworks, investment incentives, and other advantages.

7. **Implementation Planning:**

Once the location has been determined, detailed factory planning begins. This includes architectural design, logistics planning, compliance with environmental regulations, and integration of the site into the existing production and supply chain.

A Work Breakdown Structure (WBS) is a project management tool that divides a project into smaller, manageable units. It serves to represent all the work required to achieve a project goal in a hierarchical structure. The overall project is broken down into larger components, which are in turn further subdivided into detailed work packages. These packages are the smallest units that can be planned and managed, and enable a clear assignment of tasks and responsibilities. The WBS thus provides a clear overview, facilitates planning and control, and improves communication within the project team.

Resource planning encompasses the identification and allocation of the necessary resources, such as personnel, materials, time, and budget, to successfully complete a project. It ensures that the required resources are available in the right quantity, at the right time, and in the right place. This also includes considering capacities, availability, and costs to guarantee efficient utilization and avoid bottlenecks or overloads.

A milestone plan is an overview of the important stages of a project, defined as key progress points. It serves to monitor project progress by marking specific deadlines by which certain deliverables or sub-goals must be achieved. This provides clear orientation and helps to manage the project's progress and react promptly to deviations.

A project handbook is a comprehensive document that compiles all essential information and guidelines for planning, executing, and controlling a project. It serves as a central reference for the entire project team and ensures that all stakeholders are informed about objectives, roles and responsibilities, timelines, resources, communication channels, and decision-making processes. By clearly documenting procedures, standards, and processes, the project handbook ensures a consistent way of working and helps avoid misunderstandings and inefficiencies during project implementation. It is a living document that is updated throughout the project to reflect changes and new insights.

A **Shopfloor Demand Scheme** is a strategic system used in the manufacturing industry to precisely control and synchronize material and production requirements directly on the shop floor. The goal of this scheme is to optimally align material supply and production processes with actual demand in order to achieve high efficiency, minimal inventory, and short lead times.

At the heart of the shop floor demand scheme is the idea that materials and parts are made available precisely when they are needed in production – not earlier and not later. This is often achieved through the use of just-in-time (JIT) principles or Kanban systems, which ensure that production is continuously supplied with the required materials without building up excess inventory.

The system works by capturing actual demand directly on the shop floor and immediately translating it into production orders or material requests. This happens in real time, allowing production to react flexibly and quickly to changes in demand. For example, if a particular production line requires a higher quantity of a specific part, this is immediately recorded in the system, and the material flow is adjusted accordingly to meet this demand.

Another advantage of a shop floor demand scheme is the improved transparency and communication on the factory floor. Because the system accurately and promptly reflects demand, production managers and employees can immediately see which materials and resources are needed and when they must be provided. This reduces the need for manual intervention and planning adjustments, which in turn lowers the error rate and increases efficiency.

Overall, a shop floor demand scheme supports smooth and continuous production closely synchronized with actual demand. It helps reduce costs, increase production flexibility, and shorten lead times by ensuring that all necessary materials and parts are available precisely when needed. This makes it an indispensable tool in modern manufacturing, especially in environments where high efficiency and rapid responsiveness to market changes are crucial.

Value Stream Mapping is a Lean Management method used to analyze and optimize all processes within a value chain. The goal is to identify waste, increase efficiency, and maximize customer value.

Value stream mapping considers all the steps necessary to bring a product or service from raw material or order to the finished product at the customer's location. It encompasses not only the physical processes of production but also the information flows that control these processes. By visualizing the entire value stream in detail, inefficient processes, bottlenecks, overproduction, and other forms of waste can be identified.

Value stream design process

1. Preparation and Goal Definition

At the beginning, the target state is defined, i.e., what is to be achieved with the value stream analysis. It is determined which products or services are to be analyzed and who is involved in the analysis.

2. Assessing the Current State:

The first step involves capturing and visualizing the current value stream. This includes a detailed representation of the entire process, from the receipt of raw materials or information to the delivery of the finished product. Both physical processes (such as material flow and manufacturing steps) and information flows (such as orders and control processes) are depicted.

3. Analysis of the Current State:

Once the current state has been recorded, it is analyzed to identify non-value-adding activities. The goal is to make bottlenecks, delays, unnecessary movements, overproduction, waiting times, and other forms of waste visible.

4. Development of the Target State:

Based on the analysis, an optimized target state is developed. This involves redesigning or eliminating processes to make the value stream more efficient. The focus is on maximizing value creation and minimizing waste. Lean principles such as just-in-time, Kanban, or pull systems are often implemented.

5. Implementation Planning

Once the target state has been defined, a detailed implementation plan is created. This plan specifies which measures are to be implemented in which order, who is responsible for them, and what resources are required.

6. Implementation and Monitoring:

The new value stream is implemented, and the changes are put into practice. During implementation, it is important to continuously monitor progress and ensure that the planned improvements actually achieve the desired effects.

7. Continuous Improvement

: Value stream design is an iterative process. After implementing the new value stream, the process is regularly reviewed to identify further improvement opportunities. The cycle of capture, analysis, and improvement continues to continuously optimize value creation.

A **rough layout** of a new factory is created as part of the factory planning process to provide an initial, comprehensive overview of the spatial arrangement of the most important areas and processes within the factory. It serves as a fundamental planning tool to ensure that the basic requirements for material flow, production processes, logistics, and infrastructure are optimally addressed.

The rough layout allows for the early identification of potential problems and bottlenecks that could later lead to inefficient processes or additional costs. It helps to position production lines, warehouses, administrative areas, and other key facilities in such a way that the entire production process runs as efficiently as possible.

The preliminary layout is a crucial planning tool that allows for the comparison of alternative layouts, the selection of the best options, and the creation of a solid foundation for the detailed development of the final factory layout. It helps minimize risk and ensures that all essential planning aspects are considered early on, before moving on to detailed planning and construction.

Material flow design within factory planning refers to the systematic design and optimization of the flow of raw materials, semi-finished products, and finished products within a factory. The goal is to design the material flow in such a way that production processes run efficiently, cost-effectively, and smoothly, while simultaneously minimizing unnecessary movements, waiting times, and inventory.

In detail, material flow design encompasses the planning of the routes and means of transport that move materials through the various production stages. It considers the placement of machines, storage areas, assembly stations, and shipping areas to ensure that materials are transported through the factory in the shortest and most efficient way. This also includes the use of conveyor technology, automated transport systems, and storage technologies.

A well-designed material flow system significantly contributes to a factory's productivity and competitiveness by helping to shorten production times, reduce costs, and increase the flexibility of manufacturing processes. It ensures that all logistics within the factory are optimally aligned with production requirements, ultimately leading to more efficient and leaner production.

**Logistics design** within the context of factory planning refers to the strategic design and optimization of all logistical processes both inside and outside the factory. It encompasses the planning and coordination of all activities related to the transport, storage, handling, and distribution of materials, components, and finished products.

Logistics design aims to optimize the flow of goods and information to minimize costs, shorten delivery times, and ensure the availability of necessary materials. It considers various aspects such as warehouse location, warehouse system design, the selection and implementation of transportation and handling technologies, and the integration of supply chain management.

Effective logistics design ensures that all logistical processes mesh seamlessly and are optimally aligned with production processes. This helps to avoid bottlenecks, increase flexibility, and ultimately make the entire value chain more efficient and competitive. It encompasses both internal logistics (e.g., the flow of materials within the factory) and external logistics (e.g., the procurement of raw materials and the distribution of finished products).

**Process design** in the context of factory planning refers to the development and optimization of production processes within the factory. It encompasses the detailed planning of all work steps necessary to transform raw materials into finished products. The goal of process design is to create efficient, cost-effective, and high-quality production processes that meet the requirements of the company and the market.

Various aspects are taken into account as part of the process design:

- **Process Planning**: This defines the sequence of individual production steps and how they are linked to ensure a smooth and efficient production flow.

- **Technology Selection**: This determines which machines, equipment, and technologies will be used to carry out the production steps. Selecting the optimal technology plays a central role in optimizing quality, speed, and costs.

- **Workplace Design**: The layout and equipment of workstations are planned to maximize employee productivity while meeting ergonomic and safety requirements.

- **Quality Control**: Measures and controls are integrated to ensure product quality at every stage of the production process.

Process design is closely linked to material flow design and logistics design, as it ensures that production processes are efficiently integrated into the material and logistics structures. A well-thought-out process design minimizes waste, reduces lead times, and contributes to cost reduction by structuring workflows to be optimally aligned with available resources and logistical conditions.

Overall, process design forms the backbone of factory planning, as it lays the foundation for the effective and efficient production of products and significantly influences the overall performance of the factory.

Workplace design, as part of factory planning, refers to the design and arrangement of workstations to maximize efficiency, safety, and ergonomics for employees. It is an integral part of the overall process, as it represents the interface between production processes, the technologies used, and the people working in the factory.

The goal of workplace design is to create workspaces that allow employees to perform their tasks effectively and without unnecessary strain or hazards. This includes the following considerations:

- Ergonomics: Ensuring that workplaces are designed to be physically comfortable and promote the health of employees, preventing injuries and fatigue. This includes the correct height of work surfaces, convenient access to tools and materials, and minimizing repetitive, strenuous movements.

- Efficiency: Workplaces are designed so that materials, tools, and machines are optimally arranged to avoid unnecessary walking and movement. This promotes higher productivity and reduces the time required to complete a task.

- Safety: Integrating safety measures into workplace design to minimize the risk of accidents and injuries. This can be achieved through the placement of protective devices, clear safety instructions, and consideration of escape routes.

- Flexibility: Workplaces can be designed to adapt to different tasks and production requirements. This is particularly important in modern factories that need to react quickly to changes in production.

Workplace design is closely linked to process design, as it represents the physical implementation of planned production processes. A well-designed workplace enables employees to optimize production processes, leading to higher overall productivity and quality. Combined with material flow and logistics design, workplace design contributes to the optimal functioning of the entire factory, maximizing both employee performance and well-being.

In the detailed planning phase of factory design, the previously developed concepts and layouts are refined and translated into detailed plans. The goal of this phase is to plan all aspects of the factory down to the smallest detail to ensure that construction and commissioning proceed smoothly and that the factory functions optimally.

Key steps in the detailed planning phase

1. Detailing the factory layout:

The rough layout developed in earlier phases is transformed into a detailed layout. Here, all production areas, storage areas, traffic routes, supply lines, and workstations are precisely planned and recorded in the final plans.

2. Integration of 3D Planning:

In the detailed planning phase, **3D planning** is increasingly used to enable an even more accurate and realistic representation of the factory. 3D software allows all areas of the factory to be virtually modeled. This enables a comprehensive visualization of the arrangement of machines, equipment, and workstations, which facilitates the identification of potential problems or bottlenecks. The 3D models also offer the opportunity to understand and optimize complex relationships between the various systems and structures at an early stage.

3. Planning of the technical infrastructure:

All technical systems, such as energy supply, water and wastewater systems, ventilation and air conditioning, as well as IT and communication networks, are planned in detail. The integration of these systems into the 3D model is also taken into account to ensure that all lines and connections are correctly laid and that no collisions with other components occur.

4. Specification of Machines and Equipment:

In this phase, the exact specifications of the machines and equipment are defined. This includes selecting the equipment, determining the precise installation locations, planning interfaces with other systems, and considering maintenance requirements. 3D planning helps to precisely position the machines within the layout and ensure their accessibility and ease of operation.

5. Workplace Design and Ergonomics:

The detailed design of workplaces is carried out taking ergonomic principles into account to maximize employee efficiency and safety. 3D planning allows workplaces to be virtually tested to ensure they are ergonomically optimized and that all tools and materials are easily accessible.

6. Simulation and Optimization:

Another application of 3D planning in the detailed planning phase is the simulation of material flows, production processes, and movement sequences. These simulations make it possible to verify the efficiency of the planned processes and to identify and eliminate potential bottlenecks or inefficiencies even before the factory is built.

7. Preparation for Construction:

Based on the detailed plans, the construction phase is prepared. This includes creating construction plans, coordinating with construction companies and suppliers, and planning the construction process. The 3D models also serve as a communication tool between planners, engineers, and construction companies to ensure that all parties involved have a shared understanding of the project.

During implementation within the framework of construction project management, the plan developed in the detailed planning phase is put into practice. This process encompasses several key activities that ensure the factory construction is carried out efficiently, on schedule, and within budget.

Key steps in construction project management

1. Mobilization and Preparation:

First, the construction site is set up and all necessary resources, such as materials, machinery, and personnel, are provided. It is ensured that all permits are in place and that the construction site complies with safety regulations.

2. Monitoring and Control of Construction Work:

During construction, the project management team continuously monitors progress. This includes coordinating the various trades, ensuring adherence to the construction schedule, and verifying the quality of the work performed. Regular site meetings with all parties involved ensure that everyone is on the same page and that any problems can be resolved quickly.

3. Cost and Schedule Management:

A key aspect of construction project management is monitoring costs and schedules. This ensures that construction remains within the established budget and that planned milestones and completion dates are met. This also includes managing change orders and adjusting the plan in the event of unforeseen circumstances.

4. Quality Control and Acceptance:

To ensure that the construction work meets the required standards, regular quality controls are carried out. This includes both the inspection of the construction work and compliance with the technical specifications. At the end of each construction phase, an acceptance inspection is conducted to verify that all work has been completed properly.

When purchasing machinery, equipment and technical equipment for a new factory, there are several important aspects to consider to ensure that the acquisitions meet the production requirements and are economical and efficient in the long term.

1. Requirements Analysis

Before purchasing, a thorough analysis of the requirements is necessary. This includes defining the technical specifications that the machines and systems must meet to achieve the production goals. Aspects such as performance, capacity, flexibility, and compatibility with existing systems should be considered.

2. Quality and Reliability

The quality of machinery and equipment is crucial for smooth operation. It is important to pay attention to the reliability and longevity of the products to minimize downtime and maintenance costs. Therefore, the selection should focus on proven manufacturers and technologies known for their reliability.

3. Costs and Budget

In addition to the purchase price, long-term operating costs must also be considered, including maintenance, energy consumption, and spare parts. A comprehensive cost-benefit analysis will help identify the most economical option. The possibility of financing or leasing should also be explored to optimize the investment.

4. Delivery Times and Availability

The delivery times of the machines and equipment must be coordinated with the factory's construction schedule. Delivery delays can jeopardize the entire project plan. Therefore, it is important to clarify delivery times and, if necessary, explore alternatives to avoid bottlenecks.

5. Service and Support

Reliable after-sales service is crucial for the long-term operational reliability of the machines. This includes the availability of technical support, rapid spare parts supply, and the option of regular maintenance. It is advisable to carefully examine the manufacturers' service offerings and ensure they meet your requirements.

6. Technological Compatibility:

The new machines and systems must be seamlessly integrated into the existing or planned production environment. This includes compatibility with other technical systems, automation solutions, and IT infrastructures. A lack of integration can lead to significant efficiency losses.

7. Certifications and Regulations

It must be ensured that the machinery and equipment comply with all relevant legal regulations and industry standards. This applies particularly to safety standards, environmental regulations, and energy efficiency guidelines. Compliance with these regulations is not only important for legal reasons but also contributes to the sustainability of the operation.

8. Training and Ease of Use:

The operation of the new machines should be as intuitive and simple as possible to minimize staff training time. The supplier should offer training courses to ensure that staff can operate the machines safely and efficiently.

9. Future-proofing

Future-proofing should also be considered when selecting machinery. This includes the ability to adapt or expand the machines to meet future requirements. Investments in flexible and scalable technologies can help prepare the factory for future changes.

10. Contract Drafting

The contractual terms for the purchase of machinery and equipment must be carefully negotiated. Important points include warranty conditions, liability, payment terms, and delivery conditions. It is advisable to seek legal counsel to ensure that all important aspects are contractually secured.

Purchasing machinery, equipment, and technical equipment is a complex process that requires careful planning and analysis. Considering these aspects ensures that investments optimally support production and are economically viable and efficient in the long term.

Relocation management during the construction of a new factory is a comprehensive and complex process that goes far beyond the mere physical relocation of machinery and equipment. It involves transferring the entire production capacity from an existing site to a new one without significantly disrupting ongoing operations, while maintaining or even increasing production efficiency.

The first step in relocation management is detailed planning. This involves developing schedules that cover the entire process, from dismantling the machinery to recommissioning it at the new location. It is crucial that these schedules are realistic and include sufficient buffer time for unforeseen events to prevent production downtime. The coordination of the various activities—from logistics and reinstallation to employee training—must be documented in a precise schedule.

Another important aspect is resource coordination. This includes ensuring that all necessary materials, machinery, and equipment are available at the new location in a timely manner and installed correctly. This requires close collaboration with suppliers, transport providers, and internal teams. The physical relocation of machinery is particularly critical, as it is often fragile and expensive. Therefore, the transport, securing, and reassembly of this equipment must be carefully planned and executed to prevent damage.

Employee involvement plays a central role in relocation management. Employees must be integrated into the relocation process and trained to operate the machinery and processes at the new location. This is particularly important when new technologies or changes to workflows are introduced. Training should be conducted early and comprehensively to ensure that staff can seamlessly continue working at the new site.

The test runs at the new site represent another critical phase of the relocation management. Before final commissioning, all machines and equipment must be thoroughly tested to ensure they function flawlessly and that production can commence as planned. These test runs also serve to make final adjustments and ensure that material flow and workflows are optimized.

Risk management is of paramount importance throughout the entire relocation process. It is crucial to identify potential risks such as production interruptions, delays, transport damage, or restart problems early on and to plan appropriate countermeasures. These include, for example, contingency plans, alternative supply chains, or additional resources that can be quickly mobilized in the event of complications.

Overall, relocation management is a strategic process that requires careful planning, close coordination, and precise execution. Successful implementation ensures that production capacities can be transferred efficiently and without major interruptions at the new location. This contributes to the factory operating optimally from the outset and to achieving the set goals regarding productivity and efficiency.

Staffing, or the process of recruiting personnel for a new factory, involves attracting and integrating the right employees in sufficient numbers and with the appropriate qualifications for the various positions. The process begins with a detailed needs analysis, which defines the required roles and skills. This determines which positions are necessary, what specific competencies the employees must possess, and how many employees are needed in the different areas.

The recruitment phase then follows, in which suitable candidates are sought. This can be done internally, through the transfer or further training of existing employees, or externally, by recruiting new talent. The recruitment process must ensure that the selected candidates not only meet the professional requirements but also fit the company culture.

Once the employees have been selected, the onboarding and training phase begins. It is crucial that new or reassigned employees are thoroughly prepared for their tasks. This includes training on specific machines and processes, as well as instruction in safety guidelines and quality standards. The onboarding phase should be well-structured to facilitate the transition into the new role and ensure productivity from the outset.

Throughout this entire process, it is crucial to ensure open communication and clear expectations. Employees should always know what is expected of them, what development opportunities are available to them, and how their role contributes to achieving company goals. Furthermore, aspects such as working conditions, compensation, and potential career paths must be discussed early and transparently to guarantee high employee satisfaction and retention.

When staffing, it's also important to take a long-term perspective. This means not only meeting current needs but also considering potential future requirements. Topics such as employee training, developing junior staff, and managing knowledge transfer play a crucial role here.

In summary, staffing is a complex process requiring careful planning and execution to ensure the new factory is staffed with the best available talent and effectively integrated into workflows. Targeted staffing lays the foundation for a smooth production start and the factory's long-term success.

Claim management is crucial not only during the construction of a factory, but also during the procurement and installation of machinery and equipment. In a project of this scale, numerous challenges can arise, leading to deviations from the original contract. These deviations can result in additional costs, delays, or technical problems affecting both the construction and commissioning of the factory.

During factory construction, unforeseen events such as delays in the construction schedule, changes in building regulations, or unexpected soil conditions can occur. These can necessitate additional work and costs not included in the original contract. Without effective claims management, such situations could lead to disputes between the client, contractors, and subcontractors, potentially jeopardizing the entire project.

The situation is similar when purchasing and installing machinery and equipment. Problems such as delivery delays, deviations from agreed specifications, or installation difficulties can arise. These can significantly impact the project's schedule and budget. Claim management ensures that all contractual obligations are met and that appropriate compensation or adjustments can be negotiated in the event of deviations.

Claim management is therefore essential to ensure that both the construction process and the installation and commissioning of the technical equipment proceed smoothly and within budget and on schedule. It helps to identify and resolve potential conflicts early on, before they escalate, thus contributing to the successful completion of the project.

Ramp-up management is crucial for ensuring the smooth start of a new factory or production line. This phase focuses on ensuring that all systems, machinery, processes, and personnel are optimally prepared for the start of production. An inefficient ramp-up can lead to significant problems, such as production delays, quality defects, or unexpected costs, which can negatively impact the overall success of the factory.

Effective ramp-up management allows for the early identification and resolution of potential problems before they disrupt operations. It includes reviewing and fine-tuning production processes, training staff, and conducting test runs to ensure production targets are met from the outset. Furthermore, it plays a crucial role in fostering communication and coordination between different departments and stakeholders to ensure everyone is on the same page and working together toward a successful launch.

Effective ramp-up management minimizes the risks associated with starting a new production facility. It ensures that production can be quickly ramped up, quality remains stable, and the company achieves its market launch goals. In an era where speed and efficiency represent crucial competitive advantages, a smooth ramp-up is a key factor for the long-term success of a new factory.

Project examples

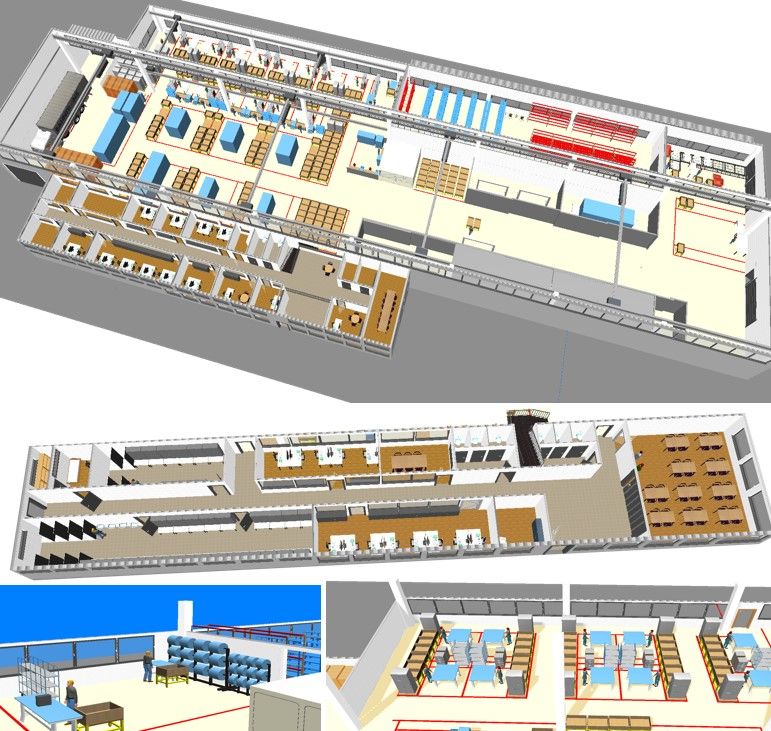

Factory redesign,

control cabinet construction

Styria / Austria

Detailed planning of logistics processes,

detailed planning of production processes,

office planning,

assembly optimization

, economic analyses

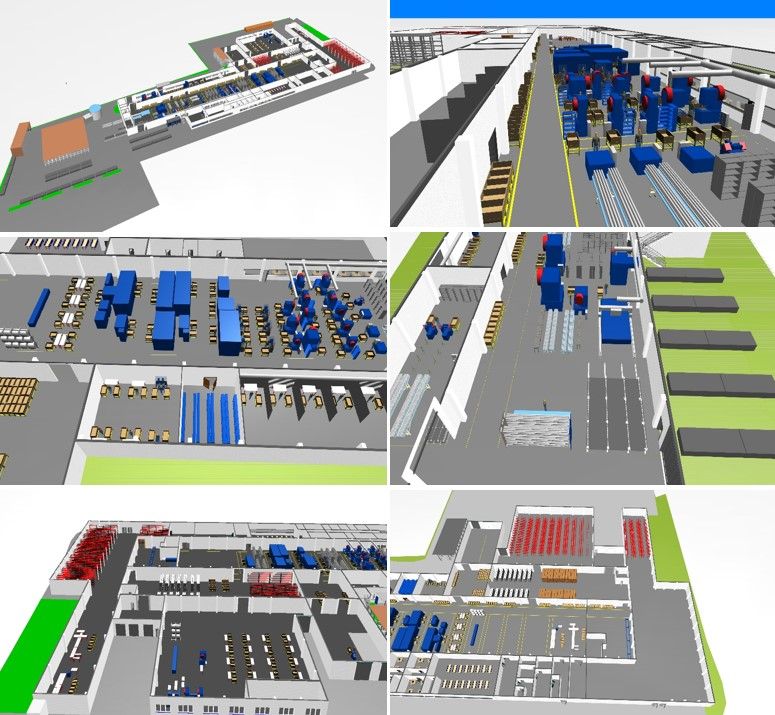

Plant expansion planning

for the recycling plant

Venice / Italy

Detailed planning of logistics processes,

detailed planning of production processes

, office planning,

infrastructure planning,

implementation planning

New factory planning,

assembly plant

Satu Mare / Romania

Warehouse planning,

assembly planning,

production process planning,

office planning,

infrastructure planning

New factory planning,

assembly plant

Styria / Austria

Analysis of logistics processes,

warehouse concept planning

, assembly planning,

infrastructure planning

Plant transfer

components plant

Western Slovakia

Analysis of logistics processes,

warehouse concept planning

, brownfield planning,

warehouse planning,

infrastructure planning,

transfer support

Factory development planning

electronics industry

Germany / Hungary

Global Manufacturing Footprint:

Detailed planning of all logistics and production processes

; warehouse optimization

; assembly optimization

; project management